Active filters:

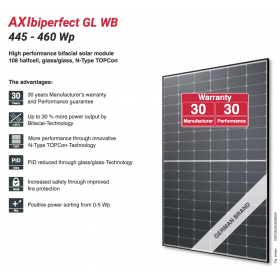

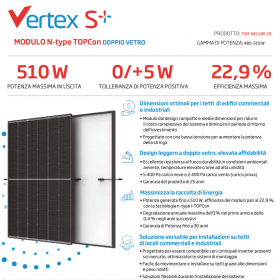

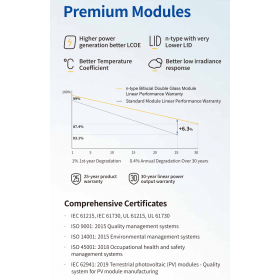

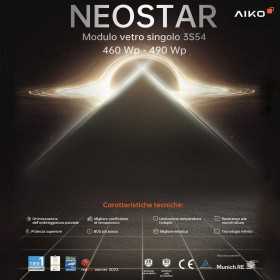

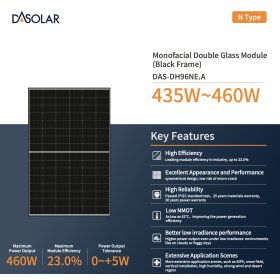

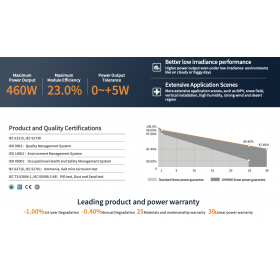

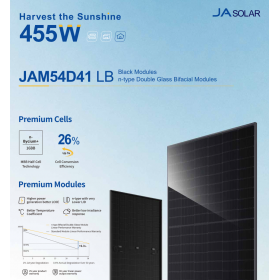

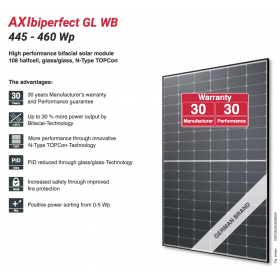

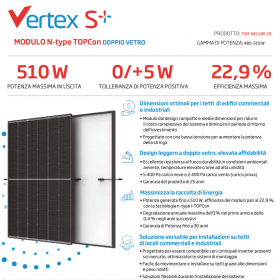

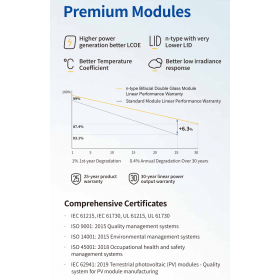

In energy engineering, a photovoltaic panel is an optoelectronic device, made up of photovoltaic modules, in turn made up of photovoltaic cells, in electrical energy through the photovoltaic effect, used as a generator. The mono or poly-crystalline modules represent the majority of the market; they are constructively similar technologies and that each photovoltaic cell is wired on the surface with a grid of conductive material that channels the electrons. Each cell is connected to the others by means of metal strips in order to form suitable circuits in series and in parallel. The need for very pure silicon through purification procedures of naturally occurring silicon oxide (SiO2, silica) raises the cost of the photovoltaic cell. A thin layer of vinyl acetate (often Indicator with the initials EVA) is placed on a back support surface, generally made of an insulating material with low thermal expansion, such as tempered glass or a polymer such as tedlar, the matrix of modules preconnected by means of the aforementioned ribbons, a second layer of acetate and a transparent material that acts as a front mechanical protection for the photovoltaic cells, generally tempered glass. After the die-casting process, which transforms the EVA into mere inert glue, the electrical terminations of the ribbons are closed in a watertight terminal block generally fixed to the rear support surface, and the result obtained is fixed to an aluminum frame, which will be useful. fixing the panel to the supporting structures designed to support it and orient it appropriately towards the sun. The models of photovoltaic modules currently available on the market have variable powers from 300 to 450wp, but the continuous evolution of construction techniques makes these data very variable, if you consider that until a few years ago the most powerful modules had a peak power of about 230-250wp.

Active filters: